We’ve talked about how speaker power handling is tested and the importance of delivering accurate test data. In the context of car audio speakers, we’ve explained that the physical size of the voice coil is a crucial element in determining how much power a speaker can handle. In this article, we’ve put together a simple, practical demonstration to show the thermal limits of a speaker.

What Defines Speaker Power Handling

Before the demonstration, we should discuss the definition of “power handling” in the context of speakers and subwoofers. Power handling describes the amount of power from an amplifier that a speaker can handle without being permanently altered negatively. This negative effect could be thermal damage to the voice coil former, the speaker’s suspension, or physical damage from excessive excursion. For example, too much low-frequency information fed into a small midrange driver might cause the voice coil former to hit the T-yoke and cause permanent deformation.

Unlike test tones, music is very dynamic. In this context, dynamic refers to a varying average level of energy. For example, a quiet passage in a song with only a female artist singing might require only a watt of power from an amplifier. When the bass guitar and drums start playing, it might take 10 or 20 watts of power to reproduce those lower frequencies. A stick hitting a floor tom drum’s skin takes less energy than strumming the lowest note on a five-string bass. The guitar sound could last several seconds, whereas the drum strike might only be a half-second. Power over time is what builds up heat in a speaker voice coil.

Cooling Capacity Analogy

A good analogy here is a car engine. For example, a Honda Civic might have a single radiator 14 inches tall and 14 inches wide with a ½-inch thick core. Conversely, a Dodge Challenger Hellcat might have a radiator that’s 25 inches wide, 18 inches tall and 1.625 inches thick. The Honda has 98 cubic inches of cooling capacity, whereas the Dodge has about 772 inches.

We know that engines are about 20-40% efficient. So, the Honda Civic, making 150 horsepower, will waste about 50 horsepower as heat under maximum load. That’s 37.3 kilowatts of heat energy. The Big Dodge can produce 700 horsepower, and assuming a similar 33% efficiency (which is likely generous), it will produce 174 kilowatts of heat.

The purpose of a radiator is to transfer the unwanted heat produced by the engine to air. If we divide the heat produced by the engine by the cubic inches of radiator area, we get 380 watts/square inch for the Honda and 225 watts/square inch for the Dodge. Given the chance that the Challenger will likely be driven more aggressively, some extra cooling capacity is cheap insurance against overheating.

Speaker Efficiency

Unfortunately, moving coil loudspeakers are notoriously inefficient. A 6.5-inch woofer might convert 0.02% of the energy from an amplifier into sound. A mid-level 12-inch subwoofer might only convert 0.25%. So, when you feed 20 watts into the midrange driver, you get the equivalent of 4 milliwatts of sound energy in the air. The rest of that power from the amplifier is wasted as heat in the voice coil and, subsequently, the parts surrounding it.

If you stop and look at different speaker designs with increasing power handling capabilities, you’ll notice that the voice coil size increases. A larger voice coil winding has more surface area. As such, the assembly can absorb more heat before failing.

For example, the Rockford Fosgate P1650 6.5-inch Punch Series speaker is rated to handle 55 watts of power. It has a voice coil diameter of 1.0 inch. The woofers in the Power Series T1650-S component set are rated for 80 watts of power handling and use a 1.2-inch diameter voice coil. The Power T3652-S set is rated for 125 watts, and the woofers have 1.5-inch diameter voice coils. So far, it all seems to make sense. An increase in diameter from 1 to 1.2 inches for a given winding height means 20% more surface area. Going from 1.2 to 1.5 inches in diameter is 25% more area. Combine this with a voice coil winding that’s likely longer, and you have significantly more heat management capacity.

Subwoofer Voice Coils

Speaker voice coils usually have a single winding of copper around the former. Subwoofers, on the other hand, can have multiple layers. Many higher-power subwoofers have four-layer voice coils, so they might be over 3 millimeters instead of a millimeter thick. This increase in size, specifically mass, further increases power handling.

The choice of voice coil former material also affects power handling. For example, aluminum has a thermal conductivity of 210 W/m-K. This means aluminum can transfer 210 watts of heat per meter of material per degree Kelvin. Copper is even better at over 400 W/m-K. On the other hand, air is a terrible conductor of heat energy at about 0.0235 W/m-K. Aramid fibers like Kevlar are also bad, at 0.04 W/m-K. If a speaker designer wants to extract heat from the voice coil winding, they might use an aluminum former. They might use an aramid glass-fiber former if they want a material that won’t heat up. Balancing physical strength, mass and thermal conductivity are all crucial in designing a reliable, high-performance speaker or subwoofer.

Let’s Compare Voice Coil Power Handling

We’ve sourced three different voice coils for this little experiment. All have relatively short windings, measuring just under 10, 18 and 20 millimeters in height. The coils have outer diameters of 26.4, 52.7 and 76.9 millimeters. The two smallest voice coils are wrapped around aluminum formers, while the larger uses two aluminum collars connected by a glass fiber backing. One collar is behind the winding, and the other is on top to connect the cone and spider. All three have two-layer windings.

I carefully measured each coil’s impedance. The small coil is wound to a DC resistance of 6.37 ohms. The medium coil has a DC resistance of 7.07 ohms, and the smallest is 3.53 ohms. I created a spreadsheet to calculate how much voltage I should apply to each coil so that it dissipates a specific amount of power. I will start with thermal measurements with 5 watts of power, then increase to 10 watts and see how hot things get.

Speaker Voice Coil Thermal Test at 5 Watts of Power

Starting with the large voice coil, the chart below shows that the temperature rose quickly from room temperature to 125 degrees after 1 minute before settling at about 137 degrees. While that’s warm, there was no concern of damaging the voice coil winding.

The medium-sized voice coil got warmer faster. It reached 132 degrees in a minute, then tapered off to 147 degrees after three minutes.

The smallest voice coil got quite hot quite quickly. It was over 210 degrees in a minute and 288 degrees in three minutes. This isn’t enough to damage it, but that’s a reasonable amount of heat.

Speaker Voice Coil Thermal Test at 10 Watts of Power

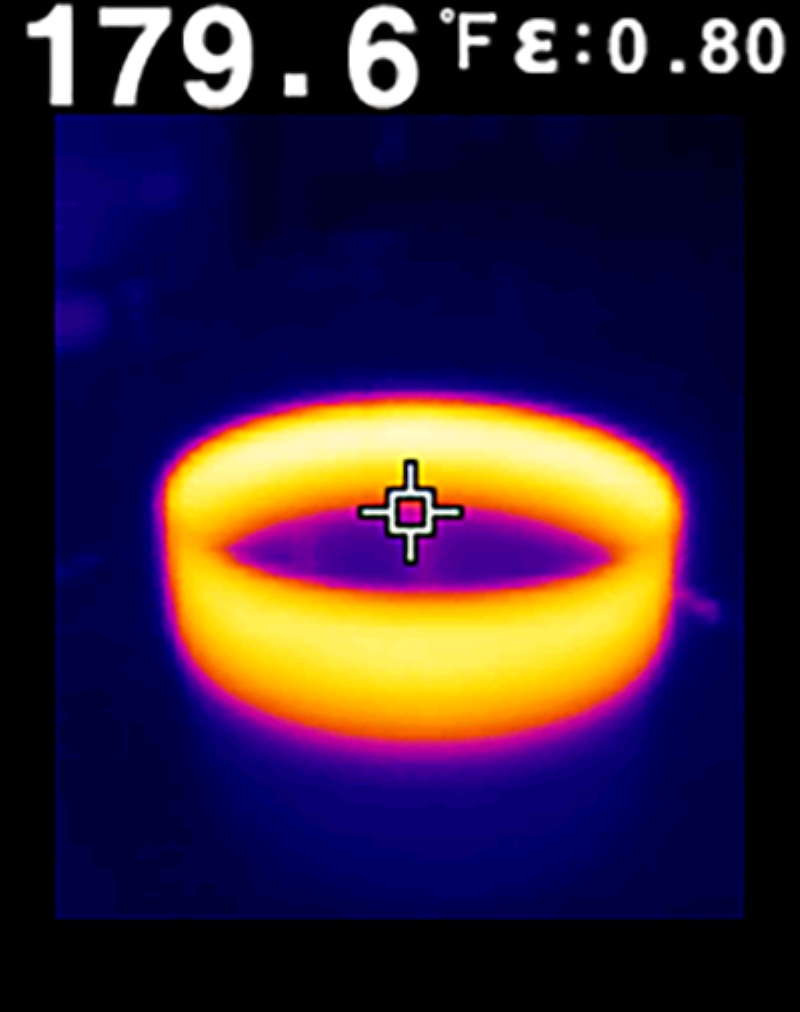

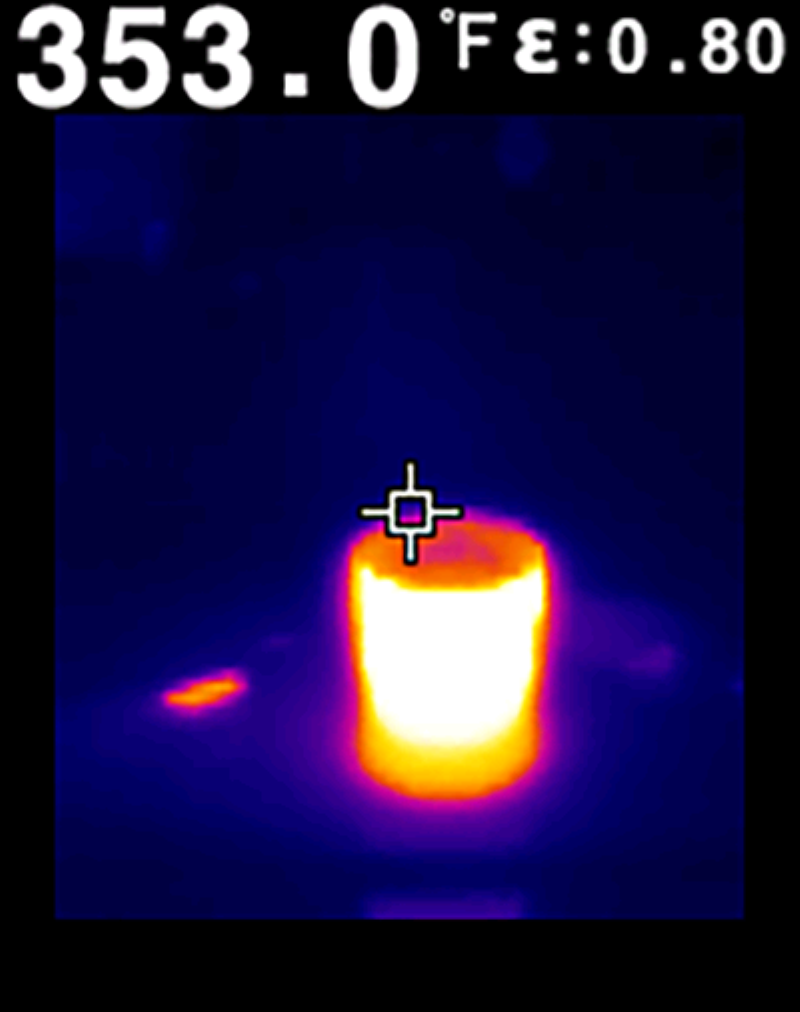

Now, let’s repeat the test using only 10 watts of power. The large coil warmed up a bit faster, tapering off around 180 degrees. The medium-sized coil followed a similar pattern, tapering off at just over 190 degrees. The tiny voice coil temperature skyrocketed almost immediately to 300 degrees, then held around 362. This temperature is the absolute upper limit of what a voice coil can handle. Prolonged use at this level would result in damage.

Undoubtedly, you’ve seen the different power ratings for Continuous and Maximum or Music power on a speaker. Constant, steady-state tones similar to what we used for this test are very hard on speakers from a thermal perspective. If this were music with 10 dB of dynamic range, you could understand how it could handle high-power transients while cooling off during quiet moments.

Another Reason Voice Coil Temperature Matters

Before we started the testing, we measured the impedance of each voice coil. The image below shows the impedance and phase plot of the small coil.

There are a few things to learn from this measurement. First, the voice coil winding doesn’t have much inductance. The impedance only starts to increase above 1 kHz. Second, the nominal impedance is at about 3.5 ohms at lower frequencies.

After the 10-watt test, I repeated the impedance measurement. The results are below.

The impedance starts at 4.2 ohms and drops to 3.8 as the voice coil cools. With very little thermal mass, the temperature drops quickly during the measurement. While the difference between 4.2 and 3.5 doesn’t seem significant, it’s an increase of 20%.

Does this impedance increase matter? Well, amplifiers output voltage, not power. The amount of power they produce depends on the impedance of the load. If an amplifier produced 5 volts RMS, the speaker would get 7.14 watts of power when cold. Once hot, the current would decrease, and the speaker would only get 5.95 watts of power. That’s not huge, but it’s a difference of 0.79 dB SPL. Suppose your installer has agonized over dialing in a digital signal processor to deliver perfectly smooth sound. In that case, a speaker with a voice coil that heats up quickly will have less efficiency once warm, altering the balance of your audio system.

Heat Management in Car Audio Speakers Is Crucial

This experiment doesn’t consider the pole piece or top plate’s proximity to a speaker to help extract heat. It also doesn’t include any benefits from the voice coil and cone moving to create airflow. However, those features don’t significantly affect the heating or cooling rate between the voice coil sizes shown here.

If you’re looking for speakers or subwoofers that can handle the most power possible, larger voice coils can handle more heat. However, they do come with some drawbacks. We’ll look at those in another article soon. In the meantime, drop by a local specialty mobile enhancement retailer to audition speakers that will sound amazing in your car, boat, or motorcycle.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.